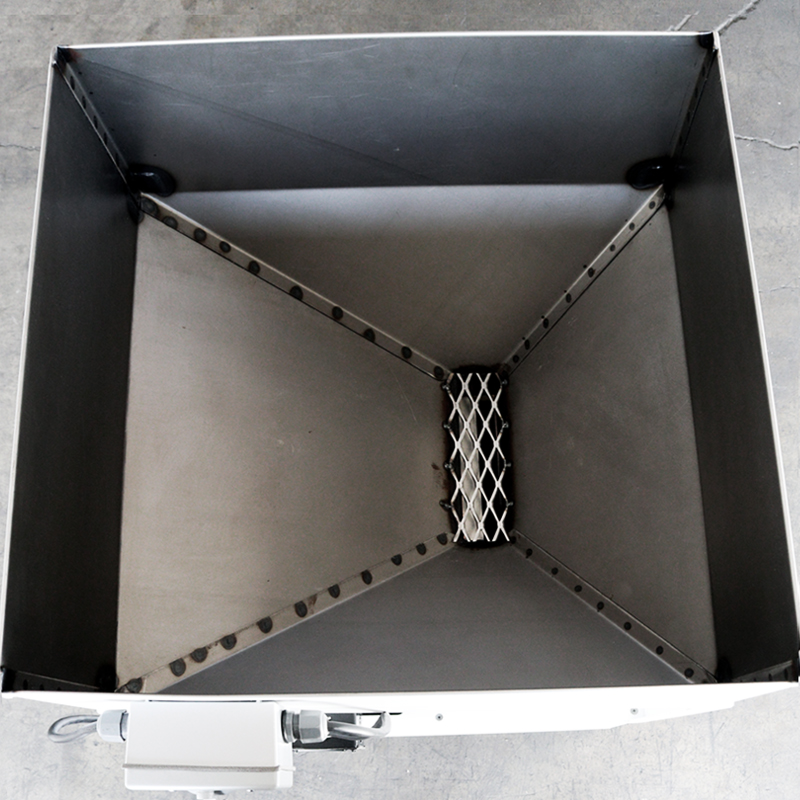

IDEAL SIZE:

Sized and priced for local brewpubs, our electric grain mills give all grain brewers the ability to control their grind, use a wider variety of malts, and innovate with new flavors and combinations. Built to exacting standards, our grain mills are designed to provide the same quality grist as the largest mills, at a price smaller craft breweries can afford.

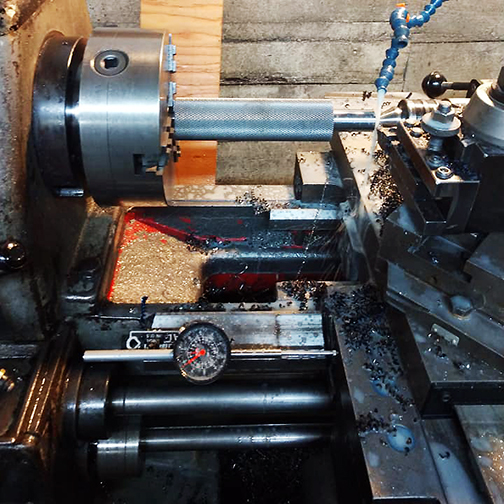

THE MAGIC IS IN THE ROLLERS:

All of our commercial malt mills are designed to give a good “crack.” A good crack will open the husk and bran of the grain, but leave the grain itself unbroken. Stout Tanks malt mills are designed for a good crack every time. All our mills have a 3-roller design, which guarantees each grain is double milled. The third roller is completely adjustable, providing absolute control over your grain.

A bad crack will lead to a stuck mash, low extraction, low clarity, and low profits. The grain contains all the sugars, which are released by soaking in the mash tun. If the grain is ground, crushed or pulverized too much, it will turn to flour, creating a muddy mess in your mash tun, a stuck mash nightmare. If your mash has too much flour, the wort cannot filter through during vorlauf, and will be left in the mud in your mash tun. A bad crack can also release too many fines into your mash, reducing the clarity of your beer, and releasing tannins from the husks and bran, giving off flavors.

DURABILITY:

All of our electric grain mills 3 rollers that are “diamond knurled” and case hardened. We carve the diamond knurl pattern by hand on every roller. The knurls are sized and shaped to crack the husks and bran, but not grind the grain to flour. Every diamond knurled roller is case-hardened in high heat to 60 Rockwell of hardness. These rollers are extremely durable and will last many years of use with your all grain brewing system.